Newest company in AXIS incubator produces a biodegradable synthetic fiber

How do you make a traditional plastic material sustainable?

If you ask Oliver Shafaat, founder of Sci-Lume Labs, your eco-friendly creation needs to meet certain requirements.

- It has to be biodegradable, something that can go back into the soil at the end of its life

- It has to be melt-processable, so it can be shaped into the product you need

- It has to be recyclable

- And finally, it has to be usable in current machines and infrastructure

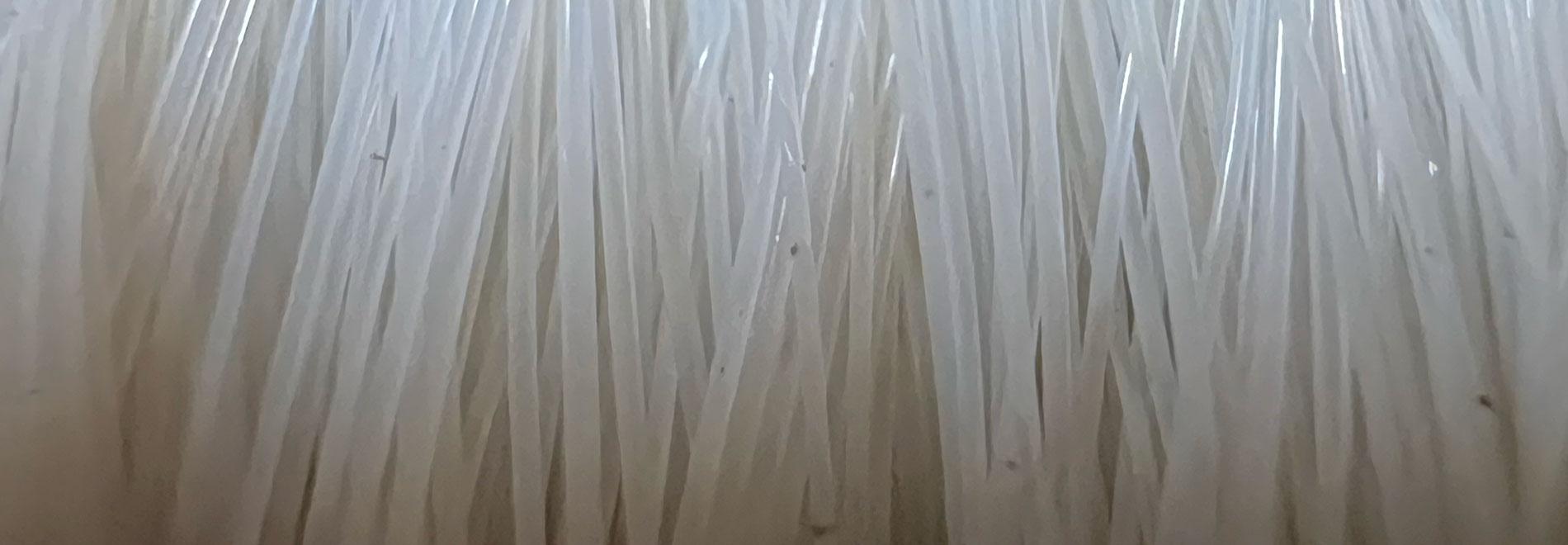

Shafaat thinks he has all that and more with Sci-Lume’s patent-pending product Bylon, a biodegradable synthetic fiber that could change the clothes production industry.

The problem

Sci-Lume Labs is the newest tenant of AXIS Powered by Francis Tuttle Technology Center, which operates a state-certified small business incubator. Cara Evans, director of AXIS, said the new company represents a growing market in the world.

"Sustainable startups and investments are one of the fastest growing sectors in global entrepreneurship," Cara Evans, director of AXIS, said. "AXIS FT is so excited to welcome Sci-Lume Labs to our certified business incubator. Oliver’s product is a great example of how you don’t have to sacrifice quality to be eco-friendly."

Synthetic fibers are derived from oil. They are plastics that are broken down and molded into the threads that make clothing items like Lycra leggings, polyester shirts, nylon shorts, or khaki shorts that include a cotton-polyester blend.

Producing clothes in this way has an environmental impact. Garments rip, tear, and grow old, and once discarded, the synthetic fibers do not break down. At the end of their life, the majority of these items will just sit in a dump heap until they are burned for energy, which adds pollutants into the air.

It's no secret environmental activists see these materials as barriers to any meaningful progress in the battle against pollution and climate change. But there are also very good reasons why clothes continue to be made out of synthetic fibers.

"Synthetic fibers and plastics are really amazing materials," Shafaat said. "They are very strong and really cheap to produce."

Even clothes made from natural fibers like cotton or wool have an environmental impact when used to mass-produce clothing as it requires the large-scale use of land, water, fertilizers, and pesticides, Shafaat said. And other clothing items made from more Earth-friendly materials are so expensive to produce that they are restricted to those who can afford them.

So Shafaat set out on a mission.

"I can make fibers and textiles in a way that is doing good for society," he said.

The solution

Shafaat’s first job out of school was with a biotech company in Japan, where he lived for several years with his Oklahoma-born wife. This company was working on several projects that involve the manufacture of synthetic products that have ecological properties.

For example, their "holy grail," Shafaat said, was to synthetically create the strong silk that spiders use to make their webs. This sparked Shafaat’s interest in synthetic fibers.

"I started to think of different alternatives," he said.

His research led him to Bylon, a new product that would eliminate the downsides of plastic fibers. The patent on Bylon is still pending, but Shafaat is confident in its ability to one day replace traditional synthetic fibers.

It is biodegradable, recyclable, and melt-processable. It even fits in the current machines used to make nylon, Lycra, polyester, and other synthetic fibers, so there is no need to create a new system to produce it.

The product will be synthesized at an off-site laboratory, then shipped to Sci-Lume’s space at AXIS, where they can process it into the fiber. The plan is to then sell the thread to clothing manufacturers.

Shafaat said AXIS will be a huge help when it comes to setting up that business-to-business operation.

"I want to make sure all the other ducks are in a row," he said. "This product is good, and people want it, but I also need to know what it takes to build a brand and know what a profit and loss sheet looks like. This way, I can not only build a product to succeed, but I can build a company to succeed."

On the current track, Sci-Lume will be producing Bylon at the AXIS space by the end of the summer.