"There are a lot of companies looking for this type of skill set."

It’s common for family members to gravitate toward a job or industry.

The Claytons have taken that to a new level.

Jonathan Clayton is in his first year of the Advanced Manufacturing training program at Francis Tuttle Technology Center but is already somewhat familiar with it. His dad, Michael, brother, Steven, and sister, Teresa graduated from the class and now have jobs using the skills they learned and the recognized industry certifications they received.

“I’m the fourth Clayton to be taking this class,” Jonathan said. “It’s worked out well for everyone so far.”

Jonathan had a job in IT, but he wanted to do something different. He knew Advanced Manufacturing would open up opportunities for him because his family now works in diverse careers.

For example, his brother Steven is in industrial maintenance at Kimray. He works on machines that create and maintain vital oil field equipment.

“I work on the CNC (computer numerical control) machines and all of the technology they have here,” Steven said. “Every day is something different.”

Teresa works within the medical industry. Her job is to maintain the machines and tools that doctors use daily to treat patients.

“I do repair and preventative maintenance on medical devices,” she said. “We do blood pressure monitors, patient monitoring,

fetal monitoring; anything in the hospital will come through my hands, but some of the higher-level equipment will be shipped off to the manufacturer.”

Their father, Michael, works for OG&E and performs maintenance work on substations. Jonathan said he could see himself doing similar work, but he’s keeping his options open.

“There are a lot of companies looking for this type of skill set,” Jonathan said. “So I’m going to wait and see what the best opportunity is.”

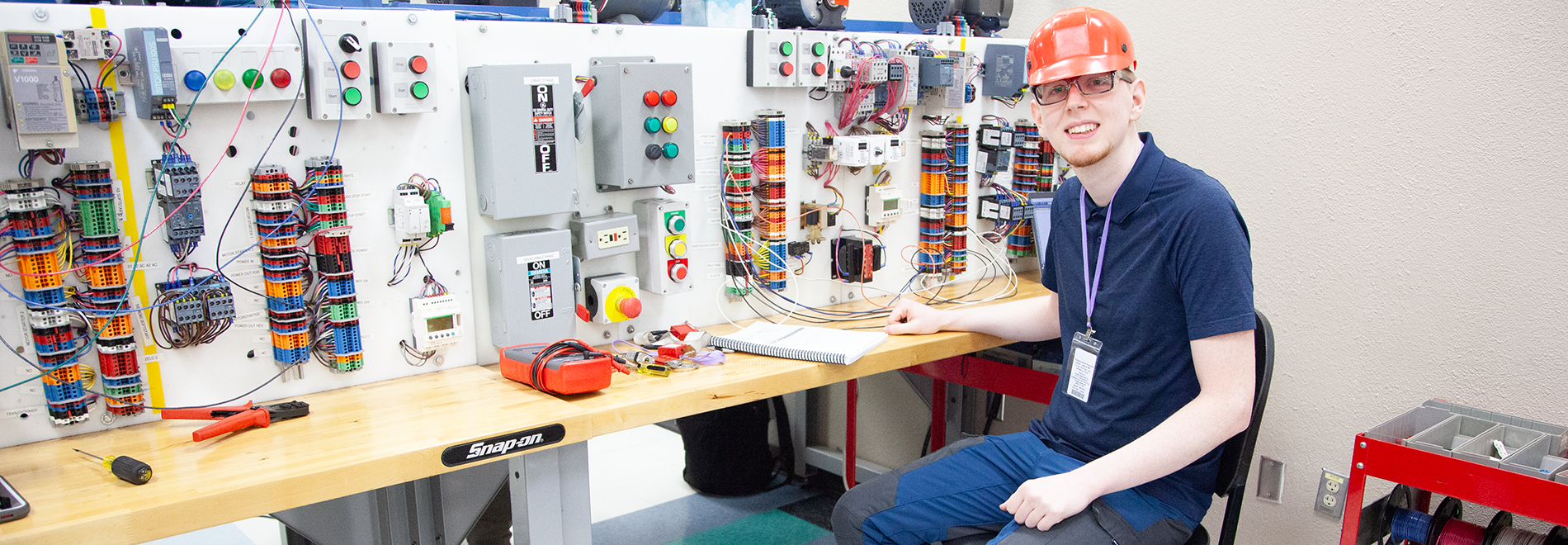

Advanced Manufacturing trains students on various industrial processes to prepare them for the jobs they want. Depending on their chosen track, they learn about control systems, instrumentation, industrial electronics, fluid power, robotics, and programmable applications.

“We started out by learning industrial mechanics, which is more the nuts and bolts stuff,” Jonathan said. “Then we learned industrial electricity, which focused on safety and learning the correct processes.”

Much of what students learn in Advanced Manufacturing applies across many industries. Teresa said there was a learning curve when it came to some of the medical machinery she works on, but the hands-on nature of the program helped her settle in

quickly.

“Just getting your hands on so many different things taught me a lot,” she said. “So when I got to the hospital, it wasn’t as big of a deal.”

Jonathan said while he has always enjoyed working with his hands, knowing his family members had succeeded in their jobs motivated him to enroll in Advanced Manufacturing. Many students end up with job offers before they finish, he said.

“I think my dad had done it four years prior to me starting, and he told me to go and do that,” Steven said. “I definitely prefer working with machines and technology, so it pretty well suited me. A representative from Kimray came and talked to our class about positions that were opening up. It all lined up for me.”